Tungsten Alloy CO., Ltd.

since 2011 please scroll

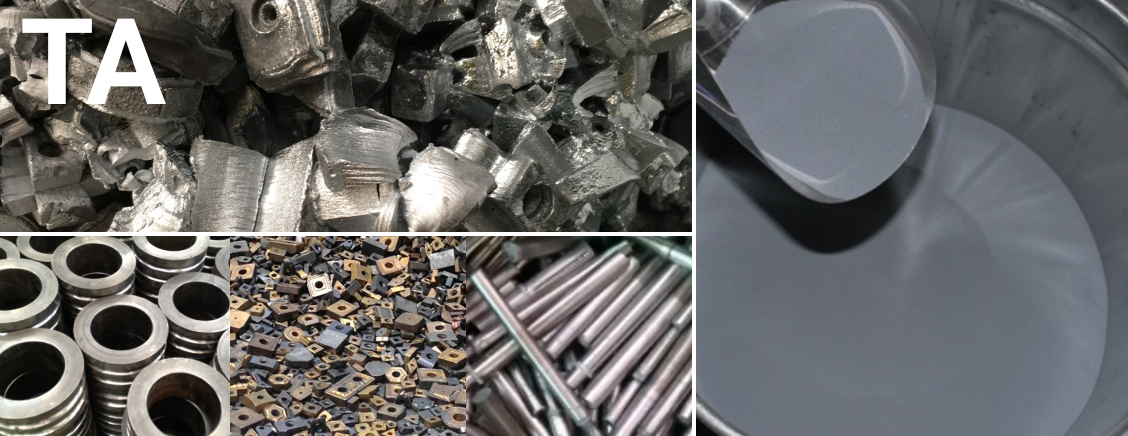

TA Co., Ltd. is a Company Specializing in Reclaiming of Tungsten Hard Metal Scrap.

We wish to express our gratitude to all our customers, who have supported us in enjoying continuous growth. Our company, TA, was estabilished in 2011 as a venture firm with the corporate ideology of “Eco friendly sustrainable development.”

Our entire staff has continued to work hard to produce and suppy high quality, innovative, products to better meet customer demands. We strive to improve quality through continued technological development. As our first achievement, we have created a system for mass production of powder by recycling tungsten carbide and tungsten heavy alloy scrap.

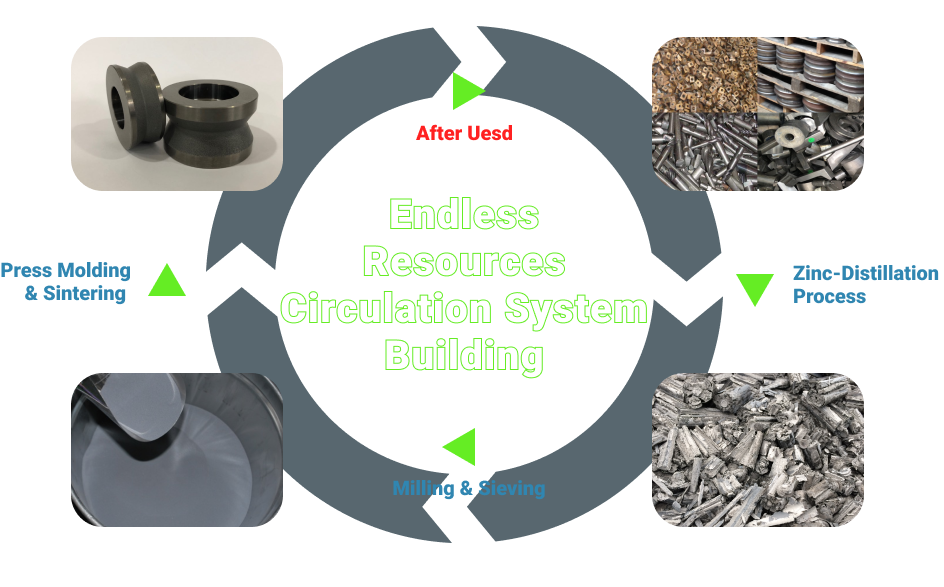

Through development of a creative production process and through quality assurance, we aim to improve the quality of recycled powder to the level of “virgin” powder. We wish to be a proactive player in addressing future environmental changes by realizing the virtuous cycle for resources usage where tungsten can be recycled continuously.

TA pots the highest priority in meeting our commitments to customers.

Established TA Co., Ltd.

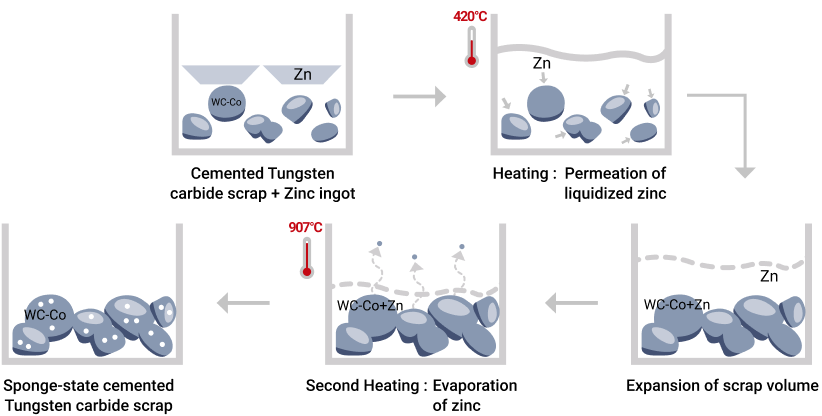

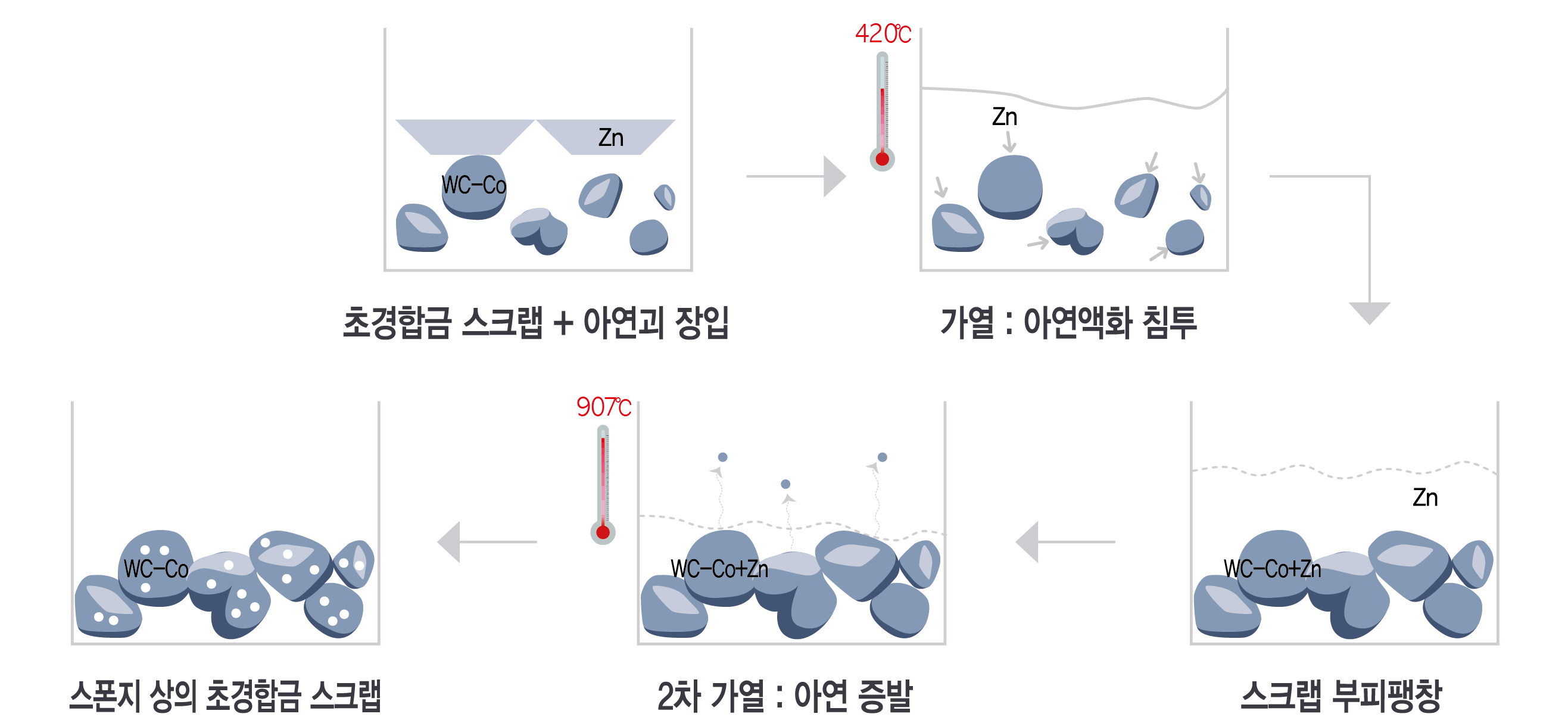

Created a mass production system to recycle tungsten carbide and tungsten heavy alloy scrap by zinc process for the first time in Korea

Certified as a venture company by the Korea Technology Finance Corporation(KOTEC)

Developed the Metal Tungsten Briquettes through tungsten scrap for special steel manufacture

Established the Research & Development Center authorized by the Korea Industrial Technology Association (KOITA) - Cert N’ 2012112072

Built the Reclaim Furnace for the zinc process with TA’s own technology

Successfully completed the R&D : ‘Project on recycling tungsten heavy scrap and tungsten carbide scrap to reclaimed powder’ supported by Korea Industrial Complex Corp(KICOX)

Certified as a Promising Export Firm by the Small & Medium Business Administration(SMBA), Republic of Korea – Cert N’ 14 Kwangju/Jellanam-do - 27

Successfully completed the R&D : ‘Recycled Tungsten carbide powder size control for Hardfacing Cord welding wire’ supported by SMBA

Patent registered for ‘Manufacturing Process of Tungsten Briquette’ – Patent N’ 10-1459095

Successfully completed the R&D : ‘Low binder & High Quality Metal Tungsten Briquettes’ supported by SMBA & POSCO

MOU with Jeollanam-Do Defence Venture Center of DTaQ for Business supports

Approved ISO 9001:2008 /KS Q ISO 9001:2009

Registered as a Supplier of Europe Tungsten Company

Built the Sintering Production line

Patent Registered for “Cemented Tungsten Carbide Part and Manufacturing Processes of it for Drilling Bit for Tap Hole in Blast Using the Reclaimed Tungsten Carbide Powder”

APPROVED ISO 9001:2015

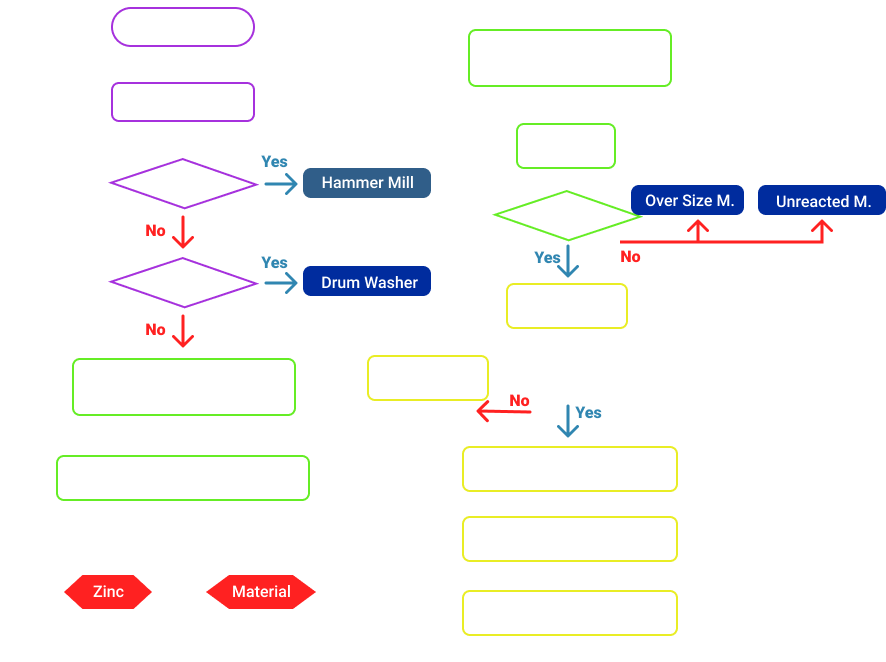

WC Scrap recycle system produce WC powder, such as the

components of the scrap material

100% Eco-Friendly & Most Economical

Tungsten Carbide

Tungsten Carbide  Crushed

Crushed  Metal Tungsten

Metal Tungsten  Sintered & Agglomerated

Sintered & Agglomerated  Tungsten Carbide

Tungsten Carbide Tungsten Carbide tip

Tungsten Carbide tip Tungsten Carbide

Tungsten Carbide

* Purchasing of Tungsten Carbide scrap

* Customized manufacturing reflecting customer's requirements

E-mail: jwlim@tungstenrecycle.com

Phone: 010-9427-3945 / 061-755-4806

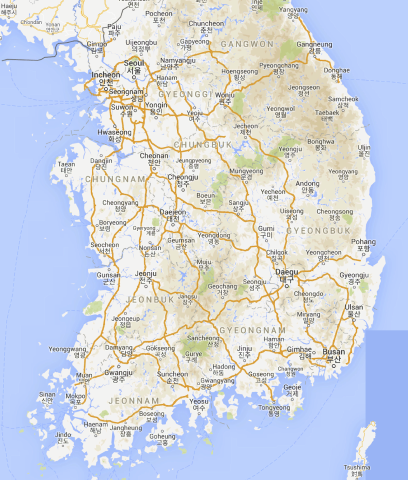

Incheon - Suncheon (TA) 311 km

Busan - Suncheon 187 km

Kwangyang - Suncheon 20 km

Seoul

Incheon

Suncheon

KwangyangBusan

Busan

Seoul

Incheon

Suncheon

KwangyangBusan

Busan